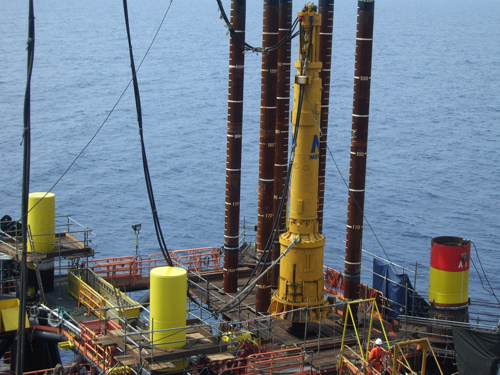

MENCK’s MHU 750T and 800S Pile Driving Systems

MENCK Hydraulic Underwater Hammer MHU –S and –T series have played an essential role in the development and progression of offshore oil & gas explorations and developments from the early beginning.

MHU’s double acting hydraulic technology combined with the modular yet compact design delivers energy transfer efficiency of up to and above 95%, making the all MHU series of hammers the lightest and yet most powerful system for every pile configuration required.

Outer Diameter (OD): 1.1 m (42-in.) - 5.2 m (205-in.)

The MHU 800S hammers are directly adaptable to pile sizes ranging from 1.1 m OD (42-in.) to 5.2m OD (205-in.). In line with its integral design considerations, these hammers can be utilized for above water and shallow subsea operations in up to 300 m water depth. Once paired with MENCK’s deepwater girdle-type powerpack, the MENCK Hydraulic Deepwater Power Pack (MHP DWS), these hammers can support installation efforts in water depths down to 3,000 m (10,000-ft) effectively and efficiently. Notably, the integral part of the technology – the MHU hammer - is one and the same for every system and size.

Key features & Benefits

- Suits free-riding or leader-guided operations

- Meets specification to be operated off drilling vessels through moonpool

- Fits into tight spaces

- Plug-and-play setup using quick-connect couplings on hydraulic, hose and umbilical connections

- Highest net rnergy vs. system weight ratio in its class making it the lightest system on the market

- >95% net energy rransfer, infinitely adjustable between to the precise energy output required

- Can be mobilized globally and deployed to 3,000 m water depth

- Flexible adaptation concept for quick-reconfiguration of system to different pile diameters

- Single-lift deployment for operations

- Closed-loop hydraulic system, configurable using biodegradable oil

- Numerous safety systems to meet highest HSE standards and improve system lifetime

- Powered by MENCK's MHP power pack(s) of variable size

- Controlled through MENCK’s one-fits-all-hammers MHC 21 control system

- Supported by MENCK’s MWI combi winch Unit for ease of deployment and recovery

- Run by MENCK’s service technicians

Operational Data & Standard Configuration

| MHU 750T | MHU 800S | |

| Minimum Nominal Energy Output (10%)[kJ] | 75 | 75 |

| Nominal Maximum Energy Output | Surface & shallow water [kJ] | 820 | 820 |

| Nominal Maximum Energy Output | Deepwater @ 1,000 m WD [kJ] | 750 | 750 |

| Oil Flow Rate @ Max. Energy [ l/min ] | 1600 | 1600 |

| Ram Weight [ton] | 45.4 | 45.4 |

| Weight of Hammer incl. Ram [ton] | 79.6 | 79.6 |

|

Anvil/Pile Sleeve Configuration Range defines the Minimum and Maximum Pile Diameter |

42" - 84" | 48" - 96" | ||

| Length overall | [m] | 17.1 | 17.6 | |

| Total Weight, above water config. | In air | [ton] | 114.6 | 120.9 |

| Total Weight, above water config. | submersed | [ton] | --- | --- |

| Total Weight, submerged config. | In air | [ton] | 139.0 | 139.9 |

| Total Weight, submerged config. | submersed | [ton] | 112 | 111 |

| Total Weight deepwater config. | In air | [ton] | --- | 155.5 |

| Total Weight deepwater config. | submersed | [ton] | --- | 106.4 |

AUXILIARY EQUIPMENT COMPONENTS

For above water and shallow water operations

- • MENCK’s Hydraulic Power Pack MHP 1600, any larger size or multiple smaller coupled together

- • 2.0-in. ID Hydraulic Lines (3x HP, 3x LP), optional on MENCK’s designated Combi Winch unit MWI

- • MENCK’s Hammer Control System MHC 21

- • Suitable Stock of Spare Parts & MENCK’s Workshop Container

For deepwater operations

- • MENCK’s Underwater Deepwater Power Pack MHP DWS 64”

- • MENCK’s Deepwater Umbilical Winch Unit MWI DWS, with suitable length umbilical

- • MENCK’s Deepwater Air Compressor unit MOC Air

- • MENCK’s Hammer System Control Unit MHC 21 DWS

- • MENCK’s Deepwater Power Container MOC DWS, with integrated control & monitoring cabin

- • Suitable Stock of Spare Parts for all MENCK System Components & MENCK DWS Workshop Container

Supplementing Services

- • Project Management and Engineering Services fully supplementing and integrating into Client's Project Team

- • Highly-qualified and fully trained Offshore Service Technician team, fully supplementing and integrated into Client’s Offshore Team